Power looms are the foundation of fabric manufacturing in the textile industry. The smooth operation of the loom affects manufacturing consistency, speed, and fabric quality. However, the power loom motor is a crucial part of every effective power loom that frequently receives insufficient attention.

Frequent breakdowns, expensive electricity costs, yarn breakage, and uneven fabric quality can result from selecting the incorrect motor. However, selecting the appropriate power loom motor can guarantee long-term dependability, lower operating costs, and increase productivity.

With over 35 years of motor manufacturing experience, we at EMP Drive, Coimbatore, work closely with textile mills to help them choose power loom motors that precisely meet their operational requirements. We’ll walk you through every step of selecting the best power loom motor for your textile mill in this article.

1. Why the Right Power Loom Motor Matters

Power looms run for long hours, often in multiple shifts. The motor has to handle:

Continuous operation

Frequent start-stop cycles

Variable load conditions

Dust- and lint-filled environments

If the motor is not designed for these conditions, it can cause:

Overheating

Speed fluctuations

Increased maintenance

Production loss

The right power loom motor ensures stable speed, smooth operation, and consistent fabric quality.

2. Understanding the Role of a Power Loom Motor

A power loom motor converts electrical energy into mechanical motion that drives the loom. Its performance directly affects:

Loom speed

Weaving consistency

Yarn tension

Fabric finish

At EMP Drive, Coimbatore, our power loom motors are engineered to deliver steady torque and reliable speed, even during long production hours.

3. Key Factors to Consider When Choosing a Power Loom Motor

1. Motor Power (HP / kW Rating)

Choosing the correct power rating is crucial.

Underpowered motors struggle under load and overheat

Overpowered motors waste electricity and increase costs

The motor power should match:

Loom type

Fabric thickness

Operating speed

Load conditions

Our experts at EMP Drive help textile mills select the exact power rating needed for efficient operation.

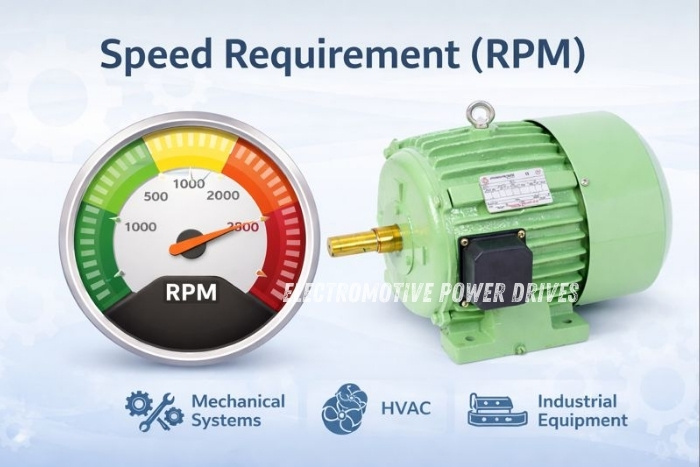

2. Speed Requirement (RPM)

Power looms require stable and consistent speed. Sudden speed changes can cause:

Yarn breakage

Fabric defects

Mechanical stress

The motor must maintain a steady RPM under varying loads. EMP Drive power loom motors are designed for smooth speed control to support high-quality weaving.

3. Duty Cycle and Operating Hours

Textile mills often run looms:

16–24 hours a day

Across multiple shifts

This means the motor must be suitable for continuous duty (S1 duty). Motors not designed for continuous operation may fail prematurely.

4. Energy Efficiency

Electricity cost is one of the biggest expenses in textile mills. Using inefficient motors leads to higher power bills.

Energy-efficient power loom motors:

Consume less electricity

Run cooler

Reduce long-term operating cost

Many textile units in Coimbatore have reduced energy expenses by switching to EMP Drive energy-efficient power loom motors.

5. Thermal Performance and Cooling

Lint and dust are common in textile environments. Poor cooling can cause motors to overheat.

The motor should have:

Effective cooling system

Good ventilation design

High-quality insulation

At EMP Drive, our power loom motors are designed to handle dusty textile conditions without overheating.

4. Importance of Stable Torque in Power Looms

Torque stability is essential for smooth weaving. Unstable torque can lead to:

Uneven fabric tension

Loom vibration

Mechanical wear

High-quality power loom motors provide consistent torque output, ensuring smooth loom movement and better fabric quality.

5. Power Loom Motor and Fabric Quality

The motor plays a direct role in fabric quality. A reliable motor ensures:

Uniform weaving speed

Reduced yarn breakage

Consistent fabric texture

Textile mills using EMP Drive power loom motors in Coimbatore often report better fabric finish and fewer defects.

6. Durability and Build Quality

Textile mills operate in tough conditions. Motors must be strong and durable. Look for:

Robust motor body

High-grade copper windings

Strong bearings

Quality insulation

EMP Drive power loom motors are built with durable materials to withstand long-term industrial use.

7. Maintenance Requirements

Frequent motor maintenance leads to downtime and increased costs.

Choosing a low-maintenance motor helps:

Reduce machine stoppages

Lower repair costs

Improve overall productivity

Our power loom motors are designed for easy maintenance and long service intervals, making them ideal for busy textile mills.

8. Real Example – Textile Mill Near Coimbatore

A textile mill near Somanur, Coimbatore, was facing frequent loom stoppages due to motor overheating and speed instability.

After replacing their motors with EMP Drive Power Loom Motors:

⚙️ Loom downtime reduced significantly

⚡ Energy consumption dropped by 15%

🧵 Fabric quality improved

🔧 Maintenance complaints reduced

This real-world case shows how choosing the right motor improves both productivity and profitability.

9. Compatibility with Existing Looms

Not all looms are the same. The motor must be compatible with:

Existing loom design

Mounting arrangement

Electrical supply

At EMP Drive, Coimbatore, we customize power loom motors to fit existing setups, reducing modification cost.

10. Noise and Vibration Control

Excessive noise and vibration can:

Damage loom components

Affect worker comfort

Reduce machine life

High-quality power loom motors operate with low vibration and noise, improving the overall working environment in textile mills.

11. Safety Considerations

Safe operation is essential in textile mills. Motors should:

Handle power fluctuations

Avoid overheating

Operate smoothly under load

Our motors are tested for safe and reliable performance in real textile conditions.

12. Energy Savings Over Motor Lifetime

Although a good power loom motor may cost slightly more initially, it saves money over time by:

Reducing electricity bills

Minimising maintenance

Increasing motor life

Most textile mills recover the investment within 1–2 years through energy savings alone.

13. Features of EMP Drive Power Loom Motors

Our power loom motors are designed specifically for textile applications:

✔ High-grade copper windings

✔ Energy-efficient design

✔ Stable speed and torque

✔ Robust cast-iron body

✔ F-Class insulation

✔ Dust-resistant construction

✔ Low vibration and noise

Every motor manufactured at EMP Drive, Coimbatore undergoes strict quality and performance testing.

14. Why Coimbatore Textile Mills Trust EMP Drive

Being located in Coimbatore, EMP Drive understands the unique needs of local textile industries. Mills trust us because we offer:

✅ 35+ years of experience

✅ Proven performance in textile applications

✅ Energy-efficient motor solutions

✅ Customised motor designs

✅ Strong local service support

We don’t just supply motors — we support long-term textile productivity.

15. Tips for Textile Mill Owners

When selecting a power loom motor:

Don’t choose based on price alone

Focus on efficiency and reliability

Consider long-term operating cost

Consult experienced motor manufacturers

Choosing the right motor today can prevent major losses tomorrow.

Conclusion

One of the most crucial choices for every textile mill is selecting the appropriate power loom motor. Smooth loom operation, reliable fabric quality, reduced energy costs, and fewer malfunctions are all guaranteed with the correct motor.

With more than 35 years of experience, we at EMP Drive, Coimbatore, assist textile mills in choosing power loom motors that best suit their operational requirements. Our motors are built to withstand demanding production requirements, demanding textile conditions, and extended operating hours.

Selecting the appropriate power loom motor is the first step if you want increased output, dependable performance, and long-term savings.

📞 Contact EMP Drive, Coimbatore today to find the perfect power loom motor for your textile mill.