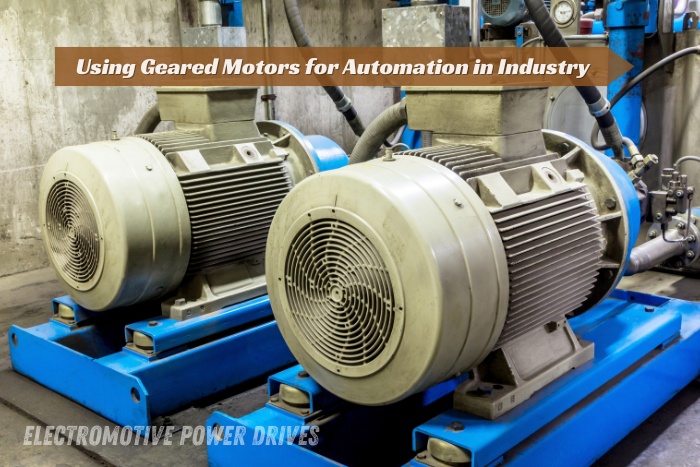

In today’s industrial world, which is growing quickly, automation has become the key to making things more efficient, cutting down on labor costs, and making more things. A geared motor is one of the most important parts of automation systems. With precision and power, these motors are an important part of driving conveyor belts, robotic arms, packaging machines, lifting systems, and other industrial machinery.

At EMP DRIVE in Coimbatore, we make geared motors of the highest quality that are specifically made to work with modern automation systems. Our motors help businesses become more efficient, use less energy, and get the best results. Let’s talk about how geared motors power industrial automation and why they are the best choice for companies that want to bring their operations up to date.

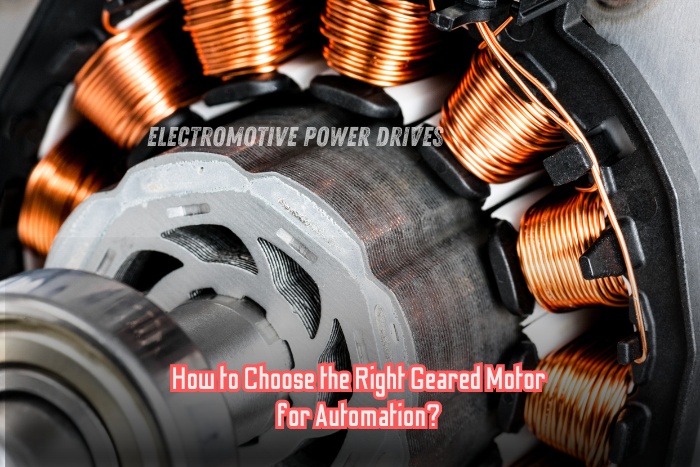

1. What Are Geared Motors? ⚙️

An electric motor and a gearbox work together to make a geared motor. This mix slows things down while increasing torque, which makes it perfect for tasks that need to be controlled, carry heavy loads, or be done with great accuracy.

✔️ It has slower speeds but more torque, which makes it perfect for automation.

✔️ Makes machines more efficient, which means they use less energy and get more work done.

✔️ It improves accuracy, which is important for industrial robots and conveyor systems.

At EMP DRIVE in Coimbatore, we make customized geared motors that meet the specific automation needs of different business sectors.

2. Why Are Geared Motors Essential for Automation? 🤖

Companies that use automation need motors that work well and give them accurate power and control. It’s best to use geared motors because they:

🔹 Ensure smooth and controlled movements.

🔹 Reduce the need for human intervention.

🔹 Enhance the accuracy and speed of operations.

Businesses can easily automate their processes with EMP DRIVE‘s geared motors, which can be used in pick-and-place robots, conveyor belts, packaging systems, or assembly lines.

3. Key Advantages of Geared Motors in Industrial Automation 🚀

a) Higher Efficiency & Energy Savings ⚡

One of the best things about geared motors is that they can use less energy while still working well.

✔️ Uses less power to generate more torque.

✔️ Minimizes heat loss, reducing electricity costs.

✔️ Longer motor life due to reduced wear and tear.

Our geared motors at EMP DRIVE, Coimbatore, help businesses save money on their electricity bills while also increasing their output.

b) Compact & Space-Saving Design 🏭

We need a lot of space in modern factories. Geared motors are small and light, which makes them perfect for automation setups that don’t have a lot of room.

📌 Fits into small spaces without affecting how well it works.

📌 It’s easier to connect to lifting systems, conveyor belts, and robotic arms.

📌 It is strong but not too heavy, which lowers the structural load on machinery.

Geared motors from EMP DRIVE are perfect for automated warehouses, food processing plants, and logistics centers because of this.

c) High Torque & Load Handling Capacity 🔄

Manufacturing, logistics, and material handling are all fields that need motors that can handle heavy loads without breaking down. When used in these situations, geared motors work best because they:

✔️ High torque, even when the speed is low.

✔️ Better load distribution keeps the machine from breaking.

✔️ The machine will last longer if it runs smoothly and without vibrations.

With geared motors from EMP DRIVE, heavy-duty automation can run smoothly and with a lot of power.

d) Precision & Motion Control for Automated Systems 🎯

In order for automation to work well, it needs precise control over speed and motion. With geared motors, businesses can be very precise and consistent in tasks like

🔹 Pick-and-place systems in manufacturing.

🔹 Robotic arms in assembly lines.

🔹 Automated guided vehicles (AGVs) in logistics.

🔹 CNC machines for metal cutting and fabrication.

We make high-precision geared motors at EMP DRIVE in Coimbatore that make motion control smooth, accurate, and effective.

e) Low Maintenance & Long Lifespan 🛠️

Motor repair and downtime are two of the biggest worries for businesses. Geared motors are made to be low-maintenance, including:

✔️ Gearboxes that are sealed to keep dust and dirt out.

✔️ Friction and wear are cut down by long-lasting lubrication.

✔️ Stronger materials that will last and work well.

Businesses can cut down on maintenance costs and increase machine uptime by using EMP DRIVE‘s geared motors. This leads to higher productivity.

4. Industries That Benefit from Geared Motors 🏢

Geared motors are very useful in automated industries because they can do many things and work quickly and accurately. Geared motors are useful in the following key industries:

1. This is used in robotic arms, CNC machines, and conveyor systems.

2. Logistics and storage are important for automated conveyor belts and systems that move things around.

3. This is used for bottling, packaging, and moving food around.

4. This part of the business runs elevators, hoists, and automated cranes.

5. Used in automated storage and retrieval systems (ASRS).

At EMP DRIVE in Coimbatore, we make geared motors that are specifically designed for each industry. These motors work perfectly in automation applications.

5. How to Choose the Right Geared Motor for Automation? ✅

Businesses should think about the following things when choosing a geared motor for automation:

🔹 Load capacity: The motor can hold how much weight.

🔹 Needs for Speed: How many RPM does it need to run smoothly?

🔹 Output power: Does the motor have enough force for the job?

🔹 Efficiency rating: Is the motor made to use little power?

🔹 Size and compatibility: Will the motor work with automation systems that are already in place

We at EMP DRIVE, Coimbatore, help companies pick the best geared motor for their automation needs so they get the best performance and the best value for their money.

6. The Future of Automation with Geared Motors 🌍

High-quality geared motors will continue to be in high demand as long as businesses keep automating tasks. Some future trends are:

✔️ Smart motors that track performance and make changes in real time thanks to integration with AI and IoT.

✔️ Eco-friendly motors use less energy and leave less of a carbon footprint.

✔️ High-precision geared motors for next-generation automation are used in advanced robotics applications.

We at EMP DRIVE, Coimbatore, work hard to stay on top of industry trends by giving businesses the most up-to-date geared motor solutions.

Conclusion – Automate Smarter with EMP DRIVE’s Geared Motors

Industrial automation depends on geared motors, which help companies be more productive, save energy, and cut costs. When you use EMP DRIVE‘s geared motors, you get the following benefits:

✅ High torque & precision for automated systems.

✅ Energy efficiency, reducing operational costs.

✅ Compact & durable design for long-term use.

✅ Low maintenance and reliable performance.

At EMP DRIVE in Coimbatore, we sell high-quality geared motors that are used in many industries to power automation. We have the right motors for your business, whether it’s for manufacturing, logistics, food processing, or moving things around.

🔹 Looking to automate your industry?

🔹 Contact EMP DRIVE, Coimbatore, today for expert motor solutions!