These days, in the fast-paced business world, safety, accuracy, and control are just as important as speed and power. Of all the different kinds of electric motors used in business, Brake Motors stand out because they can work efficiently and reliably stop. Brake motors are an important part of making sure that heavy machinery, conveyor systems, and automated production lines all work smoothly and without accidents.

For more than 35 years, EMP Drive in Coimbatore has been designing and making high-quality brake motors that meet the needs of industries all over India. We’ll go over what brake motors are, how they work, and all the different ways they can be used in this article.

1. What is a Brake Motor?

A brake motor is basically an electric motor that has a brake built into it. A regular motor only cares about turning the shaft and running, but a brake motor has a built-in brake system that lets it stop quickly and hold the load securely when the power goes out.

This makes it extremely useful in situations where:

For safety reasons, you need to stop right away.

It’s important to keep loads in one place.

For accuracy, machines have to stop at a certain point.

At EMP Drive in Coimbatore, we make brake motors with strong electromagnetic coils, long-lasting brake pads, and high-quality materials to make sure they work well and last a long time.

2. How Does a Brake Motor Work?

The working principle of a brake motor is simple yet effective:

Motor Works as It Should when the power is on, the brake coil turns on, which frees up the brake pads and lets the shaft spin freely.

When the power is turned off, either by accident or because of a stop command, the coil stops being charged. The brake pads then firmly grip the rotor, stopping the motion almost instantly.

Holding the load once the vehicle stops, the brake keeps the load in place and stops it from moving.

Because they can stop right away, brake motors are essential for safety in the workplace.

3. Why Industries Prefer Brake Motors

Industries choose brake motors over standard motors for several reasons:

Safety – Stops machines right away to avoid accidents

Precision – Stops machines at exact points, which improves the accuracy of production

Load Holding – When the power goes out, it keeps heavy loads stable.

Reduced Downtime – Stops damage and wear from movements that aren’t under control

Versatility – Does work in a lot of different areas and types of machinery

4. Common Applications of Brake Motors

In almost every industry, you can find brake motors. Let’s look at some of their most important uses:

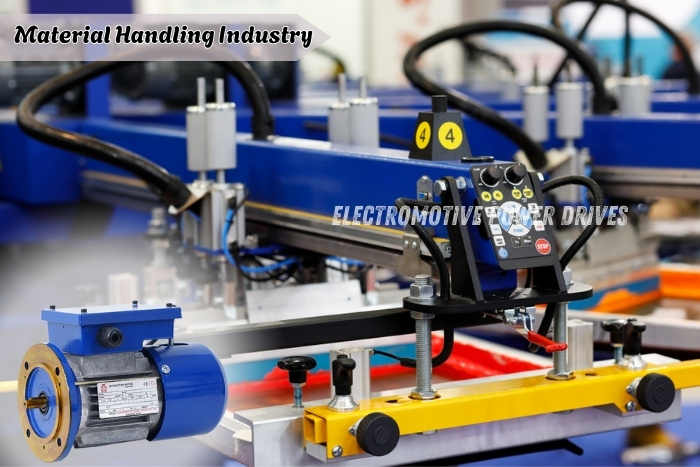

4.1 Material Handling Industry

For safe lifting and holding of heavy loads, cranes, hoists, and lifts need brake motors. They keep things from falling apart if the power goes out and make lifting go smoothly.

4.2 Textile Industry

It’s important to be precise in textile mills. Brake motors help stop looms, rollers, and winding machines exactly where they need to be stopped. This keeps fabric from being wasted and raises the quality of the production.

4.3 Packaging Industry

Machines in packaging lines have to stop at exact spots to cut, seal, or print. This accuracy is kept up by brake motors that don’t slow down production.

4.4 Conveyor Systems

It is important to have brake motors in food processing, warehouses, and assembly lines so that products don’t slip off of conveyor belts and movement can be controlled.

4.5 Machine Tools

CNC, drilling, and milling machines all have brake motors that help them stop quickly for safety and better finish.

4.6 Elevators and Escalators

Brake motors make starting and stopping safe, keeping people and machines safe from sudden movements.

4.7 Construction Industry

Concrete mixers, winches, and tower cranes all have brake motors that help control how they work and keep heavy loads safe.

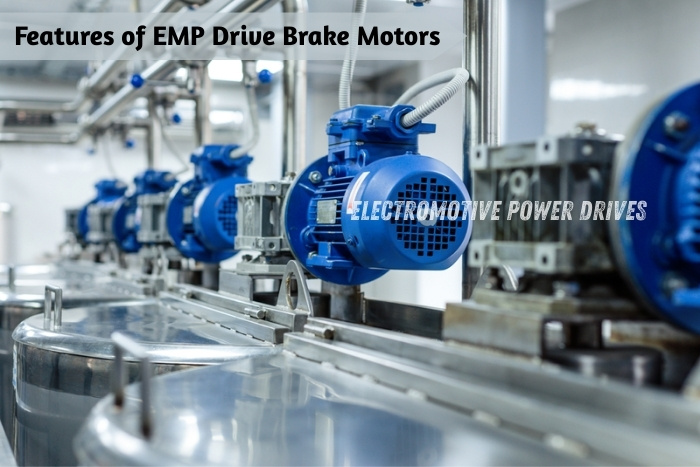

5. Features of EMP Drive Brake Motors

Here at EMP Drive in Coimbatore, we make brake motors that are perfect for Indian businesses because they:

High Torque Braking System for quick stopping

Durable Brake Linings with long life

Low Maintenance Design

Smooth and Silent Operation

Available in Multiple HP Ratings

Custom Designs for Special Applications

6. Advantages of Using Brake Motors

When you pick an EMP Drive brake motor, you get:

🔒 Enhanced Workplace Safety

⏱ Quick Stopping Time

📏 Accurate Stopping for Better Product Quality

🛠 Less Wear and Tear on Machinery

💡 Energy Savings with Efficient Design

7. Choosing the Right Brake Motor

When picking out a brake motor, think about:

Application Type – Lifting, stopping, holding, or cutting with great accuracy

Load Capacity – To lift or stop the weight

Operating Environment – Areas that are dusty, humid, and hot

Motor Power Rating – Pick the right torque and horsepower.

We at EMP Drive in Coimbatore will help you choose the best motor for your business at every step.

8. Maintenance Tips for Brake Motors

To make sure it lasts a long time and works well:

Often clean the brake pads.

Grease up parts that move.

Look over the electrical connections.

When the brake linings are worn out

Do not overload beyond what can handle.

9. Brake Motors and Industrial Safety Standards

Our brake motors are safe, reliable, and meet Indian and international standards because they are certified by BIS, ISO, and CE.

10. Why EMP Drive is the Best Choice in Coimbatore

You can trust EMP Drive to make motors in Coimbatore for more than 30 years. All over India, textile mills, factories, warehouses, and construction companies use our brake motors.

We offer:

✅ 35+ years of experience

✅ Custom-built solutions

✅ High-quality raw materials

✅ Timely delivery across India

✅ Expert after-sales service

11. Final Thoughts

Maybe the brake motor isn’t the most important part of your machine, but it is one of the most important for safety and accuracy. We make brake motors at EMP Drive in Coimbatore that keep your operations safe, effective, and productive.

Talk to our team right away if the business you work in needs brake motors that are reliable and last a long time. We’ll help you choose the best model for your needs and make sure your business runs smoothly.