Over time, industrial machinery has become more intelligent, efficient, and compact. Hollow shaft motors stand out as an outstanding engineering solution among the several motor designs that have revolutionized the way industries operate. When it comes to direct power transfer, they are small, dependable, and incredibly efficient.

For more than 35 years, we at EMP Drive, Coimbatore, have been producing hollow shaft motors for businesses in Tamil Nadu and India. Because of their performance and longevity, textile units, pumping systems, conveyors, and material handling sectors rely on our motors.

Let’s examine the engineering behind hollow shaft motors in this blog, as well as their benefits and the reasons they are crucial to contemporary industries.

1. What is a Hollow Shaft Motor?

An electric motor with a central hole (hollow shaft) that permits the driven shaft to go straight through the motor is known as a hollow shaft motor. The machine shaft is placed straight into the hollow bore of the motor, bypassing the need for couplings or other alignment systems.

This direct mounting design provides:

✅ Efficient torque transmission

✅ Space-saving installation

✅ Reduced vibration and noise

✅ Easy maintenance and alignment

In order to ensure that hollow shaft motors fit smoothly into various industrial machinery, we at EMP Drive, Coimbatore, design them with unique shaft sizes and mounting options.

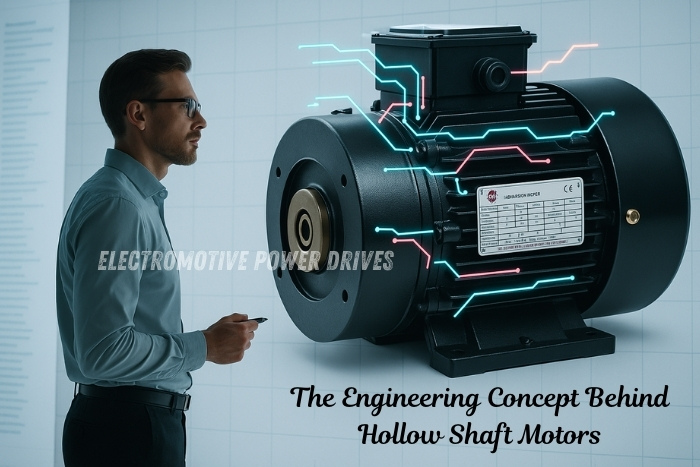

2. The Engineering Concept Behind Hollow Shaft Motors

Direct drive engineering is what hollow shaft motors are based on. There are no connections or belts in the hollow shaft motor, so it doesn’t lose power or slip. Instead, it:

Direct coupling of load shaft and motor

Better torque utilization

Less mechanical loss

Compact system design

Because of this, hollow shaft motors are very stable and use very little energy.

3. Key Components of a Hollow Shaft Motor

Each hollow shaft motor is carefully made with high-quality parts:

Stator & Rotor Assembly – Generates the magnetic field and rotation

Hollow Shaft Bore – The central hole for load shaft mounting

Bearings – High-quality bearings reduce friction and support rotation

Cooling Fan & Housing – Keeps the motor temperature under control

Insulation & Windings – Ensure durability and efficiency

We use F-class insulation, high-grade laminations, and long-lasting cast iron housings at EMP Drive to make sure that our products work well for a long time.

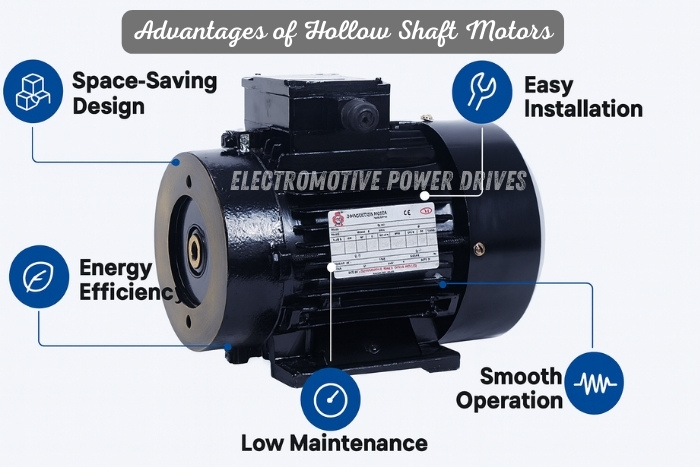

4. Advantages of Hollow Shaft Motors

🔹 Space-Saving Design

The set-up is smaller because the motor and load share the same shaft.

🔹 Energy Efficiency

Couplings don’t waste any power, so it works better.

🔹 Easy Installation

Direct mounting cuts down on alignment issues and speeds up the construction process.

🔹 Smooth Operation

When there is less shaking, the machine runs more smoothly and quietly.

🔹 Low Maintenance

Wear and tear is lessened when there are fewer parts, like connections and pulleys.

5. Applications of Hollow Shaft Motors

Our hollow shaft motors are used in many fields at EMP Drive in Coimbatore:

🧵 Textile Machines – For rollers, thread winders, and moving fabric

💧 Pumps & Borewells – Vertical hollow shaft motors for watering plants and watering irrigation

📦 Conveyors –Easy moving of goods in warehouses and packing

🏭 Food Processing Units – Machines for mixing, crushing, and labeling

⚙️ Gear Units – Automation with small gear-motor sets

🧱 Construction Industry – Machines that mix, crush, and vibrate

6. How Hollow Shaft Motors Improve Productivity

By getting rid of mechanical waste, hollow shaft motors:

⚡ Save up to 15–20% in energy costs

⏱ Reduce downtime due to simpler setups

🧩 Provide more flexibility in compact machines

📦 Improve accuracy in automated systems

This directly means that the business will be more productive and have lower operating costs.

7. Challenges in Hollow Shaft Motor Engineering

Hollow shaft motors need precise engineering, just like any other complex design. Here are some challenges:

Keeping the shaft perfectly aligned

Making sure the bearings last when big loads are applied

Making things that can work in dirty, wet, or hot places

We get around these problems at EMP Drive, Coimbatore, by:

✅ Precision machining

✅ High-grade raw materials

✅ IP55/IP65 protection options

✅ Custom bore sizes for different industries

8. Why Choose EMP Drive in Coimbatore for Hollow Shaft Motors?

People in business have chosen EMP Drive for over 35 years because we offer:

✅ Custom-engineered hollow shaft motors

✅ ISO-certified designs tested for performance

✅ Wide HP range to suit every application

✅ Rugged, dust-proof, and water-resistant enclosures

✅ Local support and quick service across Tamil Nadu

Our motors power tools that work every day, all over the world, from SIDCO estates to textile hubs in Tirupur.

Conclusion

It may look like hollow shaft motors are easy to understand, but they aren’t. They save energy, cut down on upkeep, make machines more reliable, and extend their lives by allowing direct drive systems.

We are happy to make motors at EMP Drive in Coimbatore that are both great works of engineering and useful in real life. No matter what industry you’re in textiles, farming, packaging, or building our hollow shaft motors will make your tools more productive, efficient, and long-lasting.