Productivity is the key to profitability, as any business owner knows. One crucial element frequently determines productivity in sectors that rely significantly on machinery: the motor. Any machine’s motor is its lifeblood, and selecting the incorrect kind can result in energy waste, malfunctions, increased expenses, and decreased productivity.

For more than 35 years, EMP Drive in Coimbatore has been assisting companies by producing premium motors for a variety of uses. Our collection, which includes geared motors, brake motors, single phase motors, hollow shaft motors, power loom motors, dual speed motors, and high-efficiency standard motors, is made to guarantee that companies utilize the least amount of energy while achieving optimum output.

Let’s examine how the correct motor choice immediately boosts productivity in this article and why it’s one of the best business decisions you can make.

1. Why Motor Selection Matters for Productivity

A motor is not only a machine that rotates. It affects:

⚡ Energy efficiency– calculates the amount of electricity used for each task.

⏱ Downtime – Frequent breakdowns are caused by the incorrect motor.

📦 Output quality – Precision motors save waste and increase accuracy.

🛠 Maintenance cost – A mismatched motor will deteriorate more quickly.

🌱 Sustainability– Carbon emissions are decreased by using efficient motors.

At EMP Drive in Coimbatore, we’ve witnessed numerous companies that had trouble with mismatched motors at first increase their output by only switching to the appropriate motor type.

2. Types of Motors and Their Productivity Benefits

We provide a variety of motor types at EMP Drive in Coimbatore, each of which is ideal for a certain function in increasing productivity.

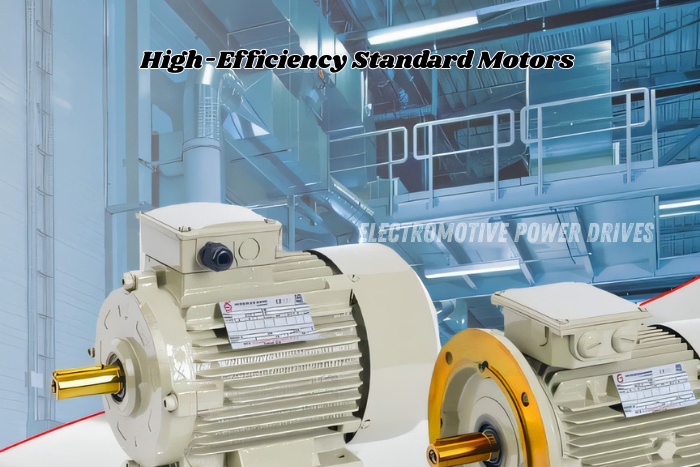

🔹 High-Efficiency Standard Motors

✅ Designed to save electricity

✅ Longer life due to less heat generation

✅ Best for continuous industrial operations

✅ Increases productivity by reducing downtime

🔹 Premium Efficiency Motors (IE3)

✅ Higher efficiency than standard motors

✅ Reduces electricity bills by up to 15–20%

✅ Perfect for heavy industries with high load demand

✅ Improves long-term savings and reliability

🔹 Brake Motors

✅ Used in cranes, lifts, hoists, and conveyors

✅ Provide instant stopping and holding power

✅ Boosts safety and precision in production

🔹 Single Phase Motors

✅ Best for small-scale industries and rural setups

✅ Easy to install, affordable, reliable

✅ Improves access to automation for small businesses

🔹 Geared Motors

✅ Combine motor and gearbox for controlled speed

✅ Deliver high torque at low speeds

✅ Reduce energy waste while improving control and accuracy

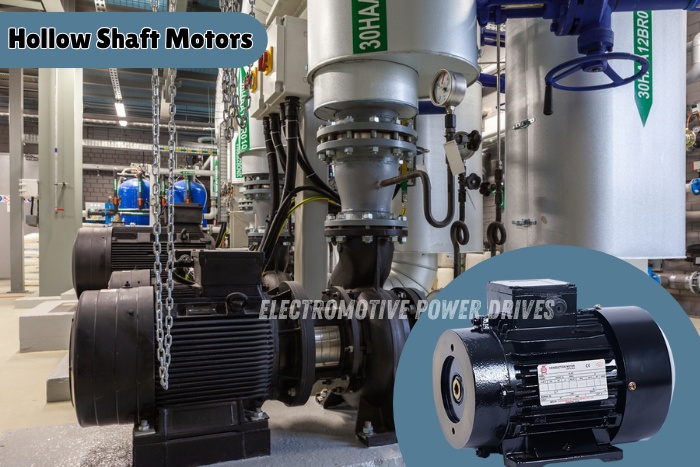

🔹 Hollow Shaft Motors

✅ Directly mountable onto load shafts

✅ Saves space, reduces alignment issues

✅ Improves efficiency in pumps, conveyors, and textile machines

🔹 Power Loom Motors

✅ Specially designed for textile industry

✅ Rugged, long-lasting, and efficient

✅ Ensures higher output in Coimbatore’s textile hubs

🔹 Dual Speed Motors

✅ Offer two speed levels in one motor

✅ Perfect for industries needing variable operations

✅ Reduce need for multiple motors, saving cost and space

3. How the Right Motor Improves Factory Productivity

✅ Energy Savings

Electricity consumption is decreased by efficient motors, which lowers expenses. The money saved can be put back into the business.

✅ Fewer Breakdowns

Less stress is placed on well-matched motors, which reduces breakdowns and stoppages.

✅ Consistent Performance

Smooth machine operation results from the proper torque and speed, which produces higher-quality goods.

✅ Flexibility in Operations

Without wasting energy, motors such as geared or dual speed motors provide flexibility.

✅ Better Safety

Accident and machine damage hazards are decreased by brake motors and thermally shielded designs.

4. Factors to Consider Before Choosing a Motor

Consider the following while selecting a motor:

⚡ Power Rating (HP/kW) – Match with machine needs

🔁 Speed (RPM)– Choose correct RPM for desired output

🔩 Torque Requirement – Essential for load-heavy applications

⏱ Duty Cycle – Continuous or intermittent operation

🌡 Environment– Dust-proof, water-resistant, or thermally protected designs may be needed

🌍 Efficiency Class – Always go for IE2 or IE3 for energy savings

To save you from having to guess, we at EMP Drive, Coimbatore, offer professional advice.

5. Maintenance Productivity

Even the greatest motor need routine maintenance. In order to increase output:

🛠 Clean air vents and housing regularly

🔧 Lubricate bearings as recommended

📏 Check alignment of pulleys and shafts

⚡ Use proper voltage and protection devices

📅 Schedule preventive maintenance

Our team at EMP Drive offers AMC (Annual Maintenance Contracts) across Coimbatore to keep your motors in top condition.

6. Why Choose EMP Drive in Coimbatore?

EMP Drive has been a reputable brand in the motor manufacturing industry for more than 35 years.

What Sets Us Apart:

✔️ Wide range of industrial motors (Standard, Premium, Brake, Geared, Hollow Shaft, Dual Speed, Power Loom)

✔️ ISO-certified, tested, and trusted by 1000+ clients

✔️ Local Coimbatore-based support team for fast service

✔️ Affordable pricing without compromising quality

✔️ Custom-built motors for specific industrial applications

We offer solutions that increase the productivity of your company in addition to selling motors.

7. The Future of Motor Selection – Smart & Efficient

Motor selection will become ever more important as businesses shift toward automation and sustainability. Anticipate:

Smart motors with IoT capabilities for predictive maintenance

Extremely effective IE4 motors to save the most energy

Compact designs for factories with limited space

Motors made of recyclable materials that are environmentally friendly

In order to keep up with international trends, we at EMP Drive, Coimbatore, are always improving our designs while keeping Indian businesses in mind.

Conclusion

Working smarter is more important for productivity than simply working harder. The best course of action in industrial operations is to choose the appropriate motor for the task at hand.

Selecting the appropriate motor type allows industry to:

✅ Save energy

✅ Reduce downtime

✅ Improve output quality

✅ Enhance safety

✅ Lower overall costs

We at EMP Drive,Coimbatore, are available to help you choose what’s ideal for your company. With our 35 years of experience in motor production, we’ll assist you in choosing motors that will fuel your expansion, boost output, and endure for many years.