Coimbatore has always been called the “Manchester of South India” because it is a place where the textile industry thrives on new ideas and dependability. Every step of the process, from using handlooms to high-tech weaving machines, rests on one important part: the motor.

Power Loom Motors have been a big part of turning traditional weaving tools into high-speed, high-output textile powerhouses.

For more than 35 years, EMP Drive in Coimbatore has been making durable and energy-efficient Power Loom Motors that help textile makers across Tamil Nadu be more productive, have less downtime, and weave better.

Let’s talk about how Power Loom Motors speed up production, why they’re important for the textile industry, and how they can help your business be more efficient and make more money.

1. Understanding Power Loom Motors

A Power Loom Motor is a special kind of electric motor that is made to keep weaving machines running smoothly and continuously.

Unlike regular motors, these are engineered to:

Handle variable loads without performance drop

Run for long hours without overheating

Deliver consistent speed for perfect fabric weaving

We make Power Loom Motors at EMP Drive in Coimbatore that have a high torque output, good insulation, and precise balance. This makes them perfect for textile settings that are hard on motors.

2. The Role of Motors in Weaving Units

Time and speed are the most important things in a moving unit. To make high-quality fabric that doesn’t break or lose its shape, each loom has to move its threads precisely.

Power Loom Motors ensure that:

The loom runs at steady RPM even under load variations

The shuttle or rapier operates at consistent tension and timing

There’s minimal vibration and downtime during continuous operation

To put it simply, a good motor is what makes the loom work and determines how much fabric is made, how well it looks, and how much money the unit makes.

3. How Power Loom Motors Increase Production Speed

⚙️ Consistent Speed and Torque

A Power Loom Motor has a power that stays the same even when the speed changes. This keeps the loom moving at the same pace and speed throughout the whole process, so there are no mistakes in the fabric and no breaks.

⚙️ Faster Acceleration

EMP Drive motors turn on quickly and have a small amount of current spike. That means the loom can reach its working speed more quickly, which saves time and energy each shift.

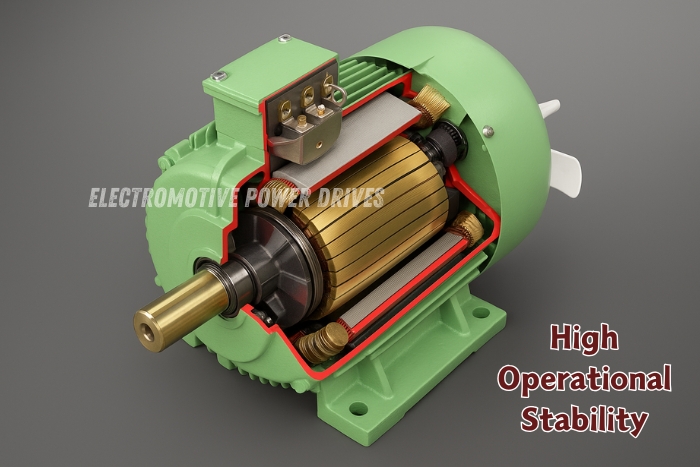

⚙️ High Operational Stability

Our motors are dynamically tuned so that they work smoothly. With less vibration, there is less downtime, and weaving processes can go faster and without breaks.

⚙️ Long Continuous Running Hours

These motors are made to work 24 hours a day, seven days a week, without getting too hot. This means that your production line can be running all the time.

⚙️ Energy Efficiency

Power Loom Motors from EMP Drive, Coimbatore are made to meet IE2/IE3 energy efficiency standards. This means that they use less energy and keep their maximum output speed.

4. Features of EMP Drive Power Loom Motors

EMP Drive makes each Power Loom Motor with great care and attention to detail.

✔️ Robust Cast Iron Body – Withstands vibration and heat during continuous operation

✔️ Copper Rotor Design – Improves torque and reduces losses

✔️ Dynamic Balancing – Ensures smooth weaving and minimal noise

✔️ F-Class Insulation – Allows longer running hours without overheating

✔️ Dust & Moisture Protection (IP55) – Perfect for Coimbatore’s industrial conditions

✔️ Custom Speed Options – Tailored for different types of looms and fabric styles

All of these features work together to make sure that your weaving gear works well, lasts a long time, and is more efficient.

5. Energy Efficiency: The Key to Profitability

In sewing units, motors can use up to 70% of all the power used. Using Power Loom Motors that use less energy will lower both your power costs and the amount of heat you make.

Benefits include:

Lower operational costs

Extended motor life

Less maintenance

Reduced environmental impact

All of our motors at EMP Drive in Coimbatore meet international efficiency standards (IE2 and IE3). This means that your business will run smoothly while also being good for the environment.

6. Why Speed Matters in Weaving

Speed has a direct effect on how much money your unit makes. You can make more fabric every day if you can run your loom faster without lowering the quality.

A high-quality Power Loom Motor:

Keeps your loom running at optimal RPM

Reduces start-stop cycles

Ensures smooth yarn movement and minimal breakage

Over time, this means fewer rejections, more output, and happier customers, all thanks to an EMP Drive motor that works well.

7. Maintenance Tips for Long-Lasting Performance

Taking care of even the best motor makes it work better. How to keep your Power Loom Motors in good shape:

✅ Keep the motor clean and free from lint or dust

✅ Check alignment and coupling regularly

✅ Lubricate bearings as per manufacturer schedule

✅ Monitor voltage supply and earthing connection

✅ Avoid overloading beyond rated capacity

✅ Use protective covers in humid environments

We also offer AMC (Annual Maintenance Contracts) at EMP Drive in Coimbatore to make sure that your motors stay in great shape year after year.

8. The EMP Drive Advantage

Why do weave shops all over Tamil Nadu choose EMP Drive Power Loom Motors?

🏭 35+ years of experience in motor manufacturing

⚙️ Custom designs for textile applications

⚡ Energy-efficient and performance-tested products

🔧 Quick local service support from Coimbatore

🧵 Trusted by leading textile units in Tirupur, Palladam, and Erode

If you pick EMP Drive, you get dependability, quality, and the power to make more things faster.

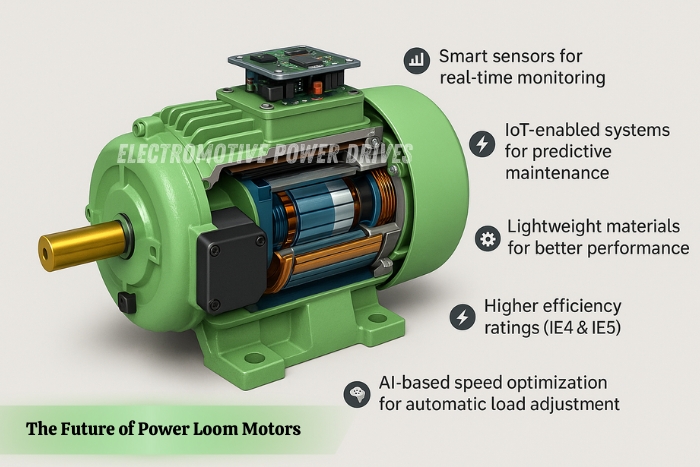

9. The Future of Power Loom Motors

The cloth business is changing quickly. These things will be on the next version of Power Loom Motors:

🌱 Smart sensors for real-time monitoring

🔋 IoT-enabled systems for predictive maintenance

⚙️ Lightweight materials for better performance

⚡ Higher efficiency ratings (IE4 & IE5)

🧠 AI-based speed optimization for automatic load adjustment

We’re already working on new technologies like these at EMP Drive to help the textile businesses in Coimbatore stay ahead of the competition around the world.

10. Why Coimbatore Is the Perfect Home for Motor Innovation

Coimbatore is a great place to make motors because it has a strong industrial base, trained workers, and an environment that is friendly to technology.

Since EMP Drive is based in Coimbatore, they are happy to support the weaving and textile industries in the area by providing motors that work well, last a long time, and are perfect for the conditions used in those industries.

It’s our simple goal to keep the looms in Coimbatore going faster, longer, and better than ever.

11. How to Choose the Right Power Loom Motor

When selecting a Power Loom Motor, consider:

Type of loom (automatic, semi-automatic, rapier, etc.)

Load requirements

Power rating (HP)

Operating hours per day

Mounting design (foot, flange, or shaft)

Ambient conditions (heat, dust, humidity)

At EMP Drive, Coimbatore, our experts help customers choose the exact motor design that works best for their production line. This ensures smooth operation and saves money in the long run.

Conclusion

Precision, speed, and dependability are very important in the weaving business, and a speed Loom Motor gives them all.

Power Loom Motors help textile units make the best fabrics and most quickly by providing steady speed, high torque, and high energy economy.

EMP Drive, Coimbatore is happy to work with hundreds of weaving units in Tamil Nadu because they know they can trust us. Our Power Loom Motors are built to be strong, fast, and stable, so they can help you weave successfully one turn at a time.

📞 Want to make your weave unit work better? Get in touch with EMP Drive, Coimbatore right away to see how our Power Loom Motors can help you get more done.