Performance, speed, and dependability are very important in today’s fast-paced business world. Every machine, from those used in building and textiles to those that pump water and make electricity, needs a strong motor that can keep working well with little upkeep.

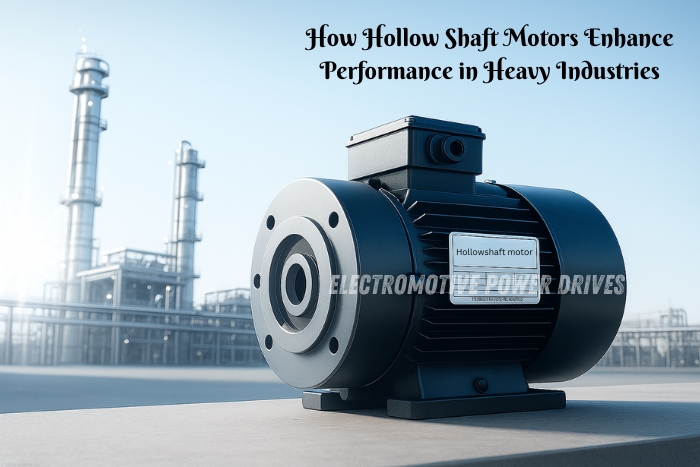

The Hollow Shaft Motor is a type of industrial motor that is becoming more and more famous in heavy industries. It is a real game-changer for companies that have to run high-load, continuous processes because of its unique engineering and better torque transmission.

For more than 35 years, EMP Drive in Coimbatore has been making hollow shaft motors that have been trusted by businesses in Tamil Nadu and India. We’ll talk about how hollow shaft motors improve performance in heavy industries and why they’re now an important part of modern production systems.

1. What Is a Hollow Shaft Motor?

An electric motor with a hole (hollow bore) going through the middle of its rotor shaft is called a hollow shaft motor. With this design, the driven shaft can go straight into the motor’s hollow hole, so there’s no need for belts, couplings, or pulleys.

To put it simply, it gives you a direct drive link, which makes moving power from the motor to the machine more efficient.

The hollow shaft motors we make at EMP Drive in Coimbatore are carefully made to provide smooth torque, high performance, and long-term longevity. This makes them perfect for heavy industries.

2. Engineering Behind Hollow Shaft Motors

The engineering behind hollow shaft motors aims to cut down on energy loss and boost torque output.

Here’s how:

The hollow bore allows the load shaft to pass directly through, providing perfect alignment.

Fewer mechanical parts mean less friction and vibration.

Improved heat dissipation keeps the motor cooler during long operations.

The result: higher efficiency, lower wear, and smoother performance.

Because of this direct-coupling concept, businesses in Coimbatore and Tamil Nadu choose EMP Drive hollow shaft motors for tough situations.

3. Why Heavy Industries Prefer Hollow Shaft Motors

✅ 1. Direct Power Transmission

Hollow shaft motors move power directly, so there is less slippage and energy loss. This is possible because they don’t use couplings or belts.

✅ 2. High Torque Output

When they’re going slowly, they have a lot of torque, which helps move heavy things.

✅ 3. Compact Design

Because they are built to take up little room, they work great in factories where floor space is limited.

✅ 4. Easy Installation

You don’t have to do any complicated alignment; just connect the load shaft straight to the motor.

✅ 5. Reduced Maintenance

When there are fewer moving parts, upkeep costs are lower and the machine lasts longer.

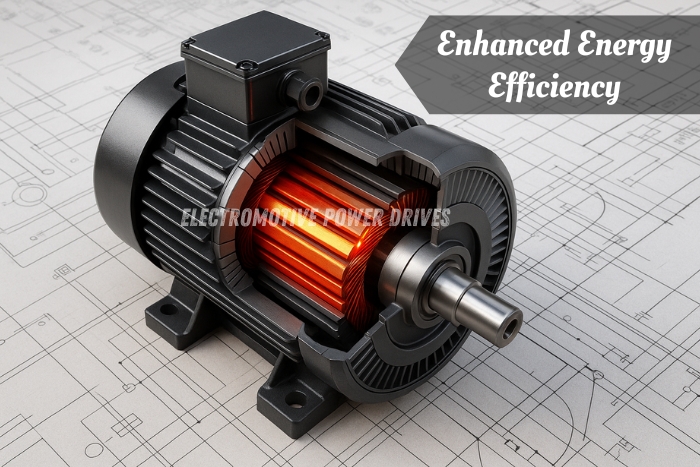

✅ 6. Enhanced Energy Efficiency

By cutting down on mechanical losses, they make more output with less power.

Every hollow shaft motor that comes from EMP Drive in Coimbatore is tested for load performance, efficiency, and balance to make sure it works consistently in any situation.

4. Applications of Hollow Shaft Motors in Heavy Industries

Hollow shaft motors can be used in many different types of industries, such as:

🏗 Construction Equipment – Concrete mixers, crushers, elevators

💧 Water and Irrigation Plants – Pumps, borewells, dewatering systems

🧵 Textile Industry – Fabric rollers, yarn winders, dyeing machinery

🏭 Manufacturing Units – Conveyors, presses, and automated machines

⚙️ Power Plants – Cooling fans, hydraulic systems

🚚 Material Handling – Hoists, lifts, and cranes

Even when they’re under a lot of stress, these motors keep their torque and motion precise, which makes them perfect for settings where they need to work all the time.

6. Features of EMP Drive Hollow Shaft Motors

EMP Drive engines are unique in the business because they:

✔️ Rugged cast-iron body for durability

✔️ High-grade copper windings for better conductivity

✔️ F-Class insulation for higher thermal tolerance

✔️ Precision-balanced rotor for vibration-free operation

✔️ IP55 protection to withstand dust and moisture

✔️ Custom bore diameters and mounting options

There is nothing else like an EMP Drive engine in the business because:

7. How Hollow Shaft Motors Enhance Performance in Heavy Industries

⚙️ 1. Increased Efficiency

Since power moves through the hollow shaft immediately, there isn’t much energy loss from friction. This means that more power is used and energy bills are lower.

⚙️ 2. Better Load Handling

Heavy pressure can be applied to these motors during start-up and operation without slowing them down or making them less stable.

⚙️ 3. Reduced Downtime

Machines last longer when they are designed with fewer parts that can break.

⚙️ 4. Smooth and Stable Operation

Less vibration means less noise and less damage to bearings and other equipment that is attached.

⚙️ 5. Space Efficiency

Ideal for fields where tools need to fit closely together, like textile and packaging lines.

⚙️ 6. Long-Term Reliability

EMP Drive motors are built to last for years, even in harsh situations, thanks to their strong construction.

8. Sustainability and Energy Savings

Hollow shaft motors not only make things more efficient, but they also help reach goals for sustainability.

🌿 Less energy waste = lower carbon footprint

🔋 Long life = fewer replacements = reduced manufacturing impact

🌍 Supports Coimbatore’s movement towards green and efficient industries

At EMP Drive, we’re happy to make motors that responsibly deliver power and support production that is good for the environment.

9. Why Heavy Industries in Coimbatore Trust EMP Drive

People in business in Coimbatore, Tirupur, Salem, and other places have believed EMP Drive for more than 30 years.

Our customers choose us because we provide:

✅ Customized engineering for every application

✅ Fast delivery and local support

✅ ISO-certified quality control

✅ Durable, high-performance motor designs

✅ Expert consultation for choosing the right model

Our motors run the most important industries in Tamil Nadu, from textile mills to pump makers.

10. The Future of Hollow Shaft Motors

There will be great progress in the next ten years:

IoT-enabled smart motors for real-time monitoring

Higher efficiency classes (IE4/IE5) for energy savings

Lightweight materials to improve speed and durability

AI-based predictive maintenance to avoid downtime

To stay ahead, we’re already coming up with new ideas at EMP Drive, Coimbatore. We’re mixing old-fashioned craftsmanship with cutting-edge technology.

Conclusion

Machinery that works hard and for long hours is very important in big industries. It needs to be reliable and efficient.

That’s exactly what Hollow Shaft Motors do: they run smoothly, have more torque, need less upkeep, and save more energy.

We’ve spent 35 years getting better at making motors at EMP Drive in Coimbatore. Our Hollow Shaft Motors are built to last and work well under pressure, helping businesses all over India be as productive as possible while wasting as little energy as possible.

📞Want to improve your equipment by adding hollow shaft motors? Get in touch with EMP Drive, Coimbatore right away, and we’ll help your business run smoothly and reliably.