The brake motor is very important in fast-moving fields where safety, control, and accuracy are important. Brake motors help stop or hold machinery in place, which keeps it from breaking, makes it safer, and boosts productivity. They are used in textile machines, cranes, conveyor belts, and cutting equipment.

Since more than 35 years ago, EMP Drive in Coimbatore has been making motors. Our high-quality brake motors meet the needs of businesses in Tamil Nadu and India. But how do you pick the right one?

This blog will give you information on what brake motors do, why they’re important, and how to pick the best one for your business.

1. What Is a Brake Motor? 🛑

A brake motor is an electric motor that has either an electromagnetic or a mechanical brake built in. If you turn off the power, the brake will stop the motor quickly or hold the load in place.

In simple terms, brake motors take the power of a motor and put it together with the safety of a brake system.

At EMP Drive in Coimbatore, we can make brake motors that are specifically made for elevators, conveyors, and hoists, among other things.

2. Why Use a Brake Motor in Industry? 🏭

Here’s why brake motors are essential in many industrial machines:

Stops the machine quickly in case of an emergency

Keeps moving parts in place when the power goes out

It lets automation systems stop correctly.

Lessens damage from moving around without control

If you work in engineering, textiles, packaging, food processing, or textiles, brake motors can make your machine run better and keep your workers safer.

3. Types of Brake Motors Explained

There are different kinds of brake motors. At EMP Drive, Coimbatore, you’ll most likely see the following:

a) DC Brake Motor

Uses a DC brake coil, even with an AC motor

Smooth and controlled braking

Great for cranes, hoists, lifts, etc.

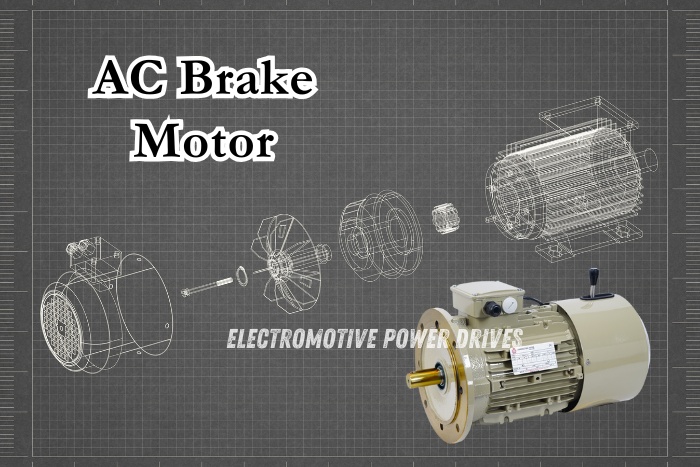

b) AC Brake Motor

Braking is done with an AC current coil

Faster and stronger braking force

Ideal for conveyor belts and mechanical tools

c) Fail-Safe Brake Motor

Brake automatically engages when power fails

Used in safety-critical applications

Best for elevators, stage equipment, etc.

d) Flange Mounted Brake Motor

Easy installation in limited spaces

Preferred in industries with compact machinery

If your business needs a motor and brake, EMP Drive can help you pick the right one.

4. Applications of Brake Motors in Industry

Brake motors are widely used in:

🏗 Construction: Lifts, cranes, hoists

🧵 Textile: Winding and unwinding systems

🏭 Manufacturing: Packaging and cutting equipment

🚢 Marine: Winches and anchor systems

🔩 Assembly Lines: Precision conveyor stops

If you are in or near Coimbatore, our team at EMP Drive can help you figure out how a brake motor can make your plant safer and more efficient.

5. Factors to Consider When Choosing a Brake Motor

✅ 1. Load Requirements

Know how much weight you’re carrying and how quickly you need it to stop. Your load torque and brake torque must be the same.

✅ 2. Braking Type

Do you need to stop quickly, hold on, or brake in an emergency? This tells you if you need fail-safe, DC, or AC brakes.

✅ 3. Mounting Type

Motors that are mounted on a flange or a foot may be needed because of limited space. You can get both of them at EMP Drive, Coimbatore.

✅ 4. Duty Cycle

A heavy-duty brake that doesn’t wear out quickly is needed for machines that stop and start a lot.

✅ 5. Environmental Conditions

Places that are dusty, humid, or hot need brake motors that are sealed and tough.

✅ 6. Motor Speed & Power

Your brakes need to work with the same RPM and horsepower as your motor. We help keep these in check here at EMP Drive.

6. Why EMP Drive Brake Motors Are a Top Choice 🏆

Here’s why industries across Coimbatore and India prefer EMP Drive brake motors:

✔ Custom Engineering – Designed to fit the load, speed, and use of your machine

✔ High-Quality Brakes – Reliable stopping power even in rough conditions

✔ Easy Installation – Small design with a variety of mounting options

✔ Low Maintenance – Strong insulation and brake linings that last a long time

✔ Support & Service – Helpful people right here in Coimbatore

Our brake motors give you power and accuracy, whether you run a sewing factory in Tirupur or a crane yard in Peelamedu.

7. Benefits of Using Brake Motors from EMP Drive

Here are the key advantages of installing our brake motors:

🔹 Instant stopping for safety

🔹 Zero backward movement on slopes

🔹 Reduced machine downtime

🔹 Better product quality with precise stops

🔹 Energy-saving during motor idle times

🔹 Improved operator confidence and control

8. How to Maintain a Brake Motor 🧰

A brake motor needs to be checked regularly, just like any other machine. To keep them running well, do the following:

Check Brake Pads – When worn out, replace

Clean Brake Housing – Prevent dust and moisture build-up

Inspect Coil – Ensure proper current supply

Test Emergency Stops – Periodically check brake performance

Lubricate Bearings – Extend life and reduce noise

We also offer maintenance kits and yearly service contracts at EMP Drive, Coimbatore, so you can rest easy.

Conclusion

Getting the right brake motor is important for more than just stopping a machine. It’s also important for safety, control, productivity, and peace of mind.

Talk to us at EMP Drive, Coimbatore if you’re not sure which brake motor is best for you. We’ll help you choose, install, and take care of your motor with the knowledge that comes from decades of developing new ones.

🚀 Let’s power your industry safely and efficiently with brake motors that deliver confidence!

📍 Visit us in Coimbatore or call EMP Drive for expert advice today.