The motor is the central component of any industrial machinery. Industrial motors make companies operational and productive, whether they are powering heavy machinery, pumps, conveyors, packing systems, or textile looms. However, motors require the right maintenance to function well and survive a long time, just like any other piece of machinery.

For more than 35 years, we at EMP Drive, Coimbatore, have been producing top-notch motors. Our motors are trusted by enterprises in Tamil Nadu and throughout India, and they include high-efficiency standard motors, premium efficiency motors, brake motors, single-phase motors, hollow shaft motors, geared motors, power loom motors, and dual-speed motors. We’ve also taught our clients over the years how routine maintenance procedures can increase motor life, lower breakdown rates, and save money.

In order to keep your equipment operating efficiently for many years, let’s examine the best techniques for industrial motor maintenance in this blog.

1. Importance of Motor Maintenance

Why is it so crucial to maintain motors?

⚡ Energy Efficiency – A well-maintained motor consumes less electricity

🛠 Reduced Downtime – Prevents sudden breakdowns that stop production

⏳ Longer Life – Good care extends the motor’s lifespan by several years

💰 Cost Savings – Saves money on repairs and replacements

🌱 Sustainability – Efficient motors reduce carbon footprint

By just adhering to basic motor care procedures, factories at EMP Drive in Coimbatore have been able to reduce maintenance expenses by up to 30%.

2. Regular Cleaning 🧹

Dust and dirt are the deadliest enemies of motors. They increase the chance of overheating, impede cooling, and block ventilation openings.

Regularly clean the air vents, cooling fins, and motor body.

To remove dust from the interior, use dry compressed air.

Water cleaning should be avoided unless the motor is watertight.

Even though EMP Drive motors are made to withstand tough environments with IP55 protection, frequent cleaning is still necessary for a long lifespan.

3. Lubrication of Bearings ⚙️

For rotation to be smooth, bearings are essential. They break down, make noise, and vibrate if they are not properly lubricated.

Tips:

Observe the manufacturer’s recommendations on the frequency of lubrication.

Use the motor’s recommended grade of grease or oil.

Avoid overlubricating because this can lead to overheating.

We employ premium double-shielded bearings at EMP Drive, which need less upkeep but still gain from regular lubrication.

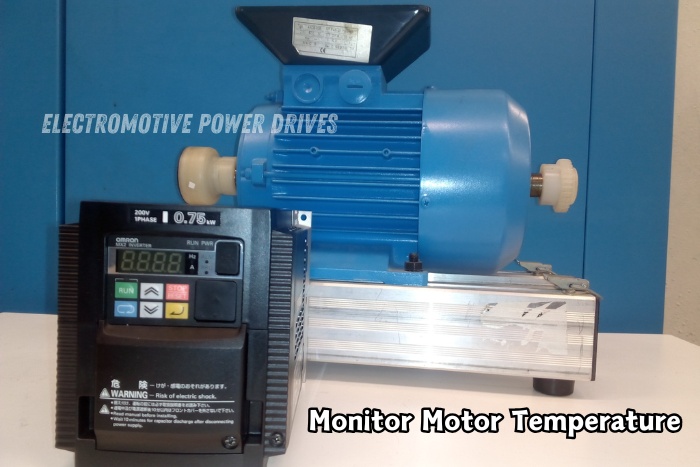

4. Monitor Motor Temperature 🌡

One of the most frequent causes of motor failure is overheating.

Preventive Measures:

Make sure the motor isn’t subjected to more load than it can handle.

Keep dust off of cooling fans and vents.

If necessary, install thermal protection systems.

To withstand extreme temperatures, use motors with F-class insulation, such as those made by EMP Drive.

5. Electrical Inspections 🔌

Motors can sustain irreparable harm from electrical problems.

What to Check:

Corrosion or loose connections

Unbalanced supply voltage

Resistance to insulation using a megger test

Condition of capacitors (for single phase motors)

Frequent electrical inspection keeps your factory’s motors operating smoothly and prevents problems.

6. Alignment and Mounting 📏

Shaft damage and bearing wear can result from improper alignment between the motor and the driven machine (such as pumps, conveyors, or compressors).

Checklist:

When installing, make use of the appropriate alignment tools.

Make sure the engine is fixed to a sturdy, vibration-free base.

Check for coupling wear and shaft alignment on a regular basis.

Although the sturdy cast iron bodies of EMP Drive motors in Coimbatore reduce vibration, proper alignment also increases dependability.

7. Protect Against Moisture and Corrosion 💧

Factories near water sources or in humid conditions require special attention.

Protection Tips:

Keep extra motors in dry places.

When operating large motors in humid environments, use space heaters.

When required, apply anti-corrosion coatings.

For applications where water is a problem, our EMP Drive hollow shaft motors and pump motors have unique sealing configurations.

8. Load Management 🏭

Continuously overloading motors shortens their lifespan.

Steps to Manage Load:

Always select the appropriate HP rating for your computer.

Never go over the motor’s specified load limit.

Upgrade to a motor with more horsepower if overload happens frequently.

We at EMP Drive assist clients in Coimbatore in choosing the ideal motor horsepower and torque rating for their particular requirements.

9. Vibration Monitoring 🔧

Unusual vibration is a sign of misalignment, imbalance, or wear on the bearings.

What to Do:

For large motors, use vibration analysis instruments.

Regularly check the pulleys and connectors.

Replace deteriorated bearings right away.

Ignoring vibration problems can significantly reduce motor life.

10. Keep Spare Parts Ready 🛠

In industries, downtime is expensive. Having necessary spare parts on hand helps you avoid significant production delays.

Typical spare parts to keep on hand:

Bearings

Capacitors

Cooling fans

Brake pads (for brake motors)

To reduce downtime, we at EMP Drive, Coimbatore, provide prompt servicing and authentic spare parts.

11. Scheduled Preventive Maintenance 📅

Instead of waiting for breakdowns, plan regular maintenance schedules:

Weekly checks for cleaning and connections

Monthly lubrication and vibration check

Quarterly electrical inspection

Annual full motor servicing

This systematic approach keeps motors reliable and efficient.

12. Use the Right Motor for the Right Job ⚡

Not every motor is made for the same function. The incorrect motor type shortens life and raises energy costs.

Use Brake Motors for cranes, lifts, and conveyors

Use Geared Motors for automation and conveyors

Use Hollow Shaft Motors for pumps

Use Dual Speed Motors where variable speed is needed

Choosing the right motor ensures better performance and longer lifespan.

13. Energy Efficiency and Motor Life 🌍

In addition to saving energy, high-efficiency motors also operate more efficiently and have a longer lifespan.

Our IE2 and IE3 class motors at EMP Drive, Coimbatore, are built to last and save energy, which helps industries reduce expenses while extending motor life.

Conclusion

The cost of industrial motors is high. You can increase production, save expenses, and prolong their life with proper maintenance procedures.

The following are the recommended practices for motor care, to sum up:

✅ Clean regularly

✅ Lubricate bearings

✅ Monitor temperature and vibrations

✅ Inspect electrical connections

✅ Ensure proper alignment and load

✅ Protect against moisture and dust

✅ Train staff and schedule preventive maintenance

Our philosophy at EMP Drive, Coimbatore, is to power industries with not only motors but also the know-how to keep them running. With nearly 35 years of experience, we offer dependable assistance along with high-quality motors to ensure your business operates uninterrupted.