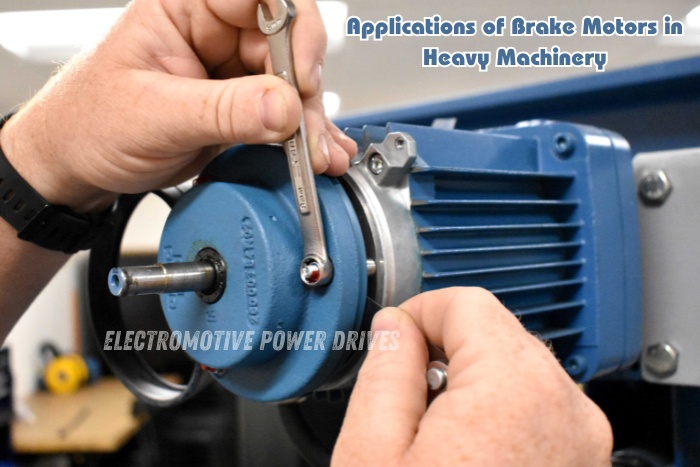

Safety and control are equally crucial in heavy industries as speed and force. Machines move large parts, manage enormous loads, and run nonstop for extended periods of time. It is crucial to safely and quickly stop a machine in such circumstances. Brake motors are essential in this situation.

A brake motor is a safety-focused drive system that guarantees machines stop precisely when needed, without delay or drift. It is more than just a motor with added parts. With more than 35 years of motor manufacturing experience, EMP Drive in Coimbatore has supplied brake motors to numerous heavy industries where load holding and precise stopping are essential.

Let’s examine the main uses of brake motors in heavy machinery, their operation, and the reasons why industries depend on them for dependable, safe operations in this blog.

1. What Is a Brake Motor?

An electric motor equipped with an electromagnetic brake is called a brake motor. The brake releases and the motor starts when the electricity is turned on. The brake immediately activates when the power is off, instantly stopping the motor.

This design ensures:

Immediate stopping

Load holding without rollback

Improved operator safety

Better control over heavy machinery

Our brake motors at EMP Drive are designed to function dependably in challenging industrial environments, heavy loads, and repeated start-stop cycles.

2. Why Brake Motors Are Essential in Heavy Machinery

Heavy machines involve:

High inertia

Large moving masses

Vertical or inclined movement

Continuous operation

Without a brake motor, machines may:

Take longer to stop

Drift after power cut

Cause accidents or damage

Put stress on mechanical components

Brake motors are crucial in heavy-duty applications because they provide regulated, instantaneous stopping, which eliminates these dangers.

3. Key Applications of Brake Motors in Heavy Machinery

1. Cranes and Hoisting Equipment

Cranes lift and move extremely heavy loads. Any delay in stopping can lead to load swing or drop.

Brake motors help by:

Holding loads securely when power is cut

Preventing rollback during lifting

Ensuring precise positioning

Brake motors are therefore essential for hoists, gantry cranes, jib cranes, and EOT cranes.

2. Elevators, Lifts, and Vertical Transport Systems

Vertical movement always carries risk. In elevators and industrial lifts, brake motors:

Stop cabins instantly during power failure

Prevent downward drift

Ensure passenger and material safety

Brake motors are essential for safe vertical transportation in industries and warehouses.

3. Conveyors in Heavy Material Handling

To prevent spills or pile-ups, conveyors carrying bulk materials such as coal, cement, ore, or metal parts must be precisely stopped.

Brake motors:

Stop conveyors instantly

Prevent backward movement on inclined belts

Improve control during loading and unloading

In mines, ports, steel mills, and cement factories, this is particularly crucial.

4. Press Machines and Forming Equipment

Press machines operate with high force and require accurate stopping at exact positions.

Brake motors ensure:

Precise stroke control

Operator safety

Reduced mechanical shock

They are extensively utilised in metal forming units, stamping machines, and hydraulic presses.

5. Rolling Mills and Steel Processing Units

High torque and heavy rotating parts are handled by steel and metal processing equipment.

Brake motors help by:

Controlling sudden stops

Preventing equipment damage

Improving operator safety

In rolling mills, controlled stopping avoids material damage and machine overload.

6. Construction Machinery

Because of the uneven loads and challenging conditions on construction sites, equipment such as mixers, hoists and material elevators need to be able to stop reliably.

Brake motors provide:

Safe load handling

Stable operation on slopes

Reduced risk of accidents

This makes them ideal for heavy construction equipment.

7. Mining Equipment

Conveyors, crushers, and hoisting systems operate in harsh environments during mining operations.

Brake motors are essential because they:

Hold heavy loads securely

Prevent uncontrolled movement

Improve worker safety

In mining, brake motors are a critical safety component, not an option.

8. Industrial Gearboxes and Heavy Drives

Brake motors are often combined with gearboxes in heavy machinery to provide both torque and stopping power.

This setup is common in:

Crushers

Mixers

Agitators

Heavy-duty conveyors

At EMP Drive, Coimbatore, we supply brake motors compatible with various gearbox configurations.

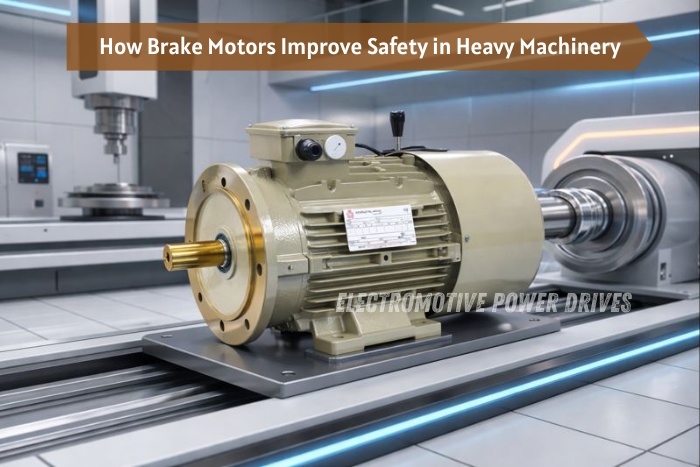

4. How Brake Motors Improve Safety in Heavy Machinery

Safety is the biggest advantage of brake motors. They:

Stop machines immediately during power failure

Prevent accidental movement

Protect operators and nearby workers

Reduce risk of load drop or machine collision

In heavy industries, this safety factor alone justifies the use of brake motors.

5. Performance Benefits Beyond Safety

Brake motors also improve overall machine performance:

Faster cycle times

Accurate positioning

Reduced wear on mechanical parts

Better control in automation systems

These benefits directly increase productivity and reliability.

6. Real Example – Heavy Industry Unit Near Coimbatore

Due to delayed machine halting, a heavy fabrication facility close to Kurichi, Coimbatore, was frequently experiencing safety problems.

After installing EMP Drive Brake Motors:

⚙️ Machine stopping time reduced drastically

🔒 Load holding improved

🔧 Maintenance complaints reduced

🕒 Production efficiency increased

This shows how brake motors make a real difference in heavy machinery operations.

7. Types of Brake Motors Used in Heavy Machinery

🔹 DC Electromagnetic Brake Motors

Quick response

Reliable load holding

🔹 AC Brake Motors

Suitable for continuous industrial use

Easy integration with control systems

🔹 Fail-Safe Brake Motors

Brake engages automatically on power loss

Ideal for safety-critical applications

8. Energy Efficiency and Brake Motors

Modern brake motors are designed to work efficiently without wasting power. They:

Reduce unnecessary mechanical braking

Minimise heat generation

Support smooth start-stop operations

At EMP Drive, our brake motors are built to balance safety and energy efficiency.

9. Maintenance Advantages of Quality Brake Motors

High-quality brake motors:

Require less frequent servicing

Have longer brake lining life

Reduce unexpected downtime

This makes them cost-effective over the long run.

10. Choosing the Right Brake Motor for Heavy Machinery

Before selecting a brake motor, consider:

Load weight

Speed requirements

Frequency of start-stop

Vertical or horizontal movement

Environmental conditions

Our technical team at EMP Drive, Coimbatore helps industries select the right brake motor for safe and efficient operation.

11. Why Industries in Coimbatore Trust EMP Drive

EMP Drive, which has its headquarters in Coimbatore, is aware of the needs of heavy industries. Companies pick us because we provide:

✅ 35+ years of motor manufacturing experience

✅ Reliable brake motor designs

✅ Strong focus on safety and durability

✅ Custom solutions for heavy machinery

✅ Local service and technical support

Conclusion

Brake motors are an essential part of heavy machinery because they provide precise control, dependable performance, and safe operation. Standard motors cannot take the place of their function in anything from presses and mining equipment to cranes and conveyors.

We produce braking motors at EMP Drive in Coimbatore to satisfy the practical needs of heavy industries. With more than 35 years of experience, we assist companies in increasing security, minimising downtime, and operating with assurance.

A braking motor is essential if your machinery must stop under regulated conditions while handling big loads.

📞 Contact EMP Drive, Coimbatore today to choose the right brake motor for your heavy machinery needs.