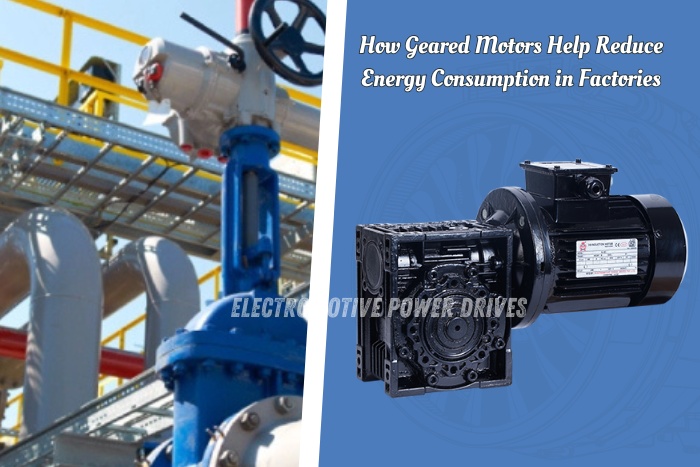

Factories are constantly under pressure to lower prices, increase efficiency, and use less energy in the cutthroat industrial world of today. Using the appropriate motor type is a straightforward yet effective method to accomplish this. Geared motors have emerged as one of the best options for lowering factory energy usage among the several options available.

Since we have been producing geared motors for more than 35 years at EMP Drive in Coimbatore, we have witnessed directly how these motors revolutionize factory operations. Let’s examine the operation of geared motors, their energy-saving properties, and their actual advantages for companies in this blog.

1. What is a Geared Motor?

An electric motor and a gearbox are simply combined to create a geared motor. The gearbox increases torque and decreases speed, while the motor supplies power and speed.

Key Benefits:

Accurate speed regulation

High torque output

Efficient power transmission

Compact and space-saving design

Our geared motors at EMP Drive, Coimbatore, are made to run everything from material handling systems and packing machinery to textile machines and conveyors.

2. Why Factories Need Geared Motors

Heavy machinery is used in factories, but not all of it requires high-speed rotation. Many call for slow, high-torque, controlled motion. Frequently, using a regular motor without a gearbox results in:

Excessive energy use

Overheating

High maintenance costs

Reduced lifespan of machines

This issue is resolved by geared motors, which provide precisely the required torque and speed neither more nor less. Energy waste is directly decreased by this optimization.

3. How Geared Motors Reduce Energy Consumption

✅ Efficient Power Transmission

Geared motors transfer power more efficiently than external pulleys or friction, which waste energy.

✅ Right Speed for the Job

High RPM is frequently unnecessary for machines. In order to save electricity, geared motors minimize superfluous speed and transform it into usable torque.

✅ Lower Load on Machines

Controlled motion lowers the overall power usage by putting less strain on the associated equipment.

✅ Reduced Start-Up Power

During starting, geared motors reduce peak energy demand by producing strong torque at low current.

✅ Less Downtime More Savings

They save energy and maintenance expenses by reducing wear and tear and extending the time between machine breakdowns.

4. Applications of Geared Motors in Factories

Our geared motors at EMP Drive in Coimbatore are employed in numerous sectors, including:

🧵 Textile Industry – Power looms, spinning machines, fabric rollers

📦 Packaging Industry – Conveyor belts, sealing and labeling machines

🏭 Automotive Manufacturing – Assembly lines, robotic arms

🏗 Construction Sector – Concrete mixers, hoists, elevators

🥫 Food Processing Units – Mixers, crushers, conveyors

🚚 Logistics and Warehousing – Lifts and handling systems

Factories claim a discernible decrease in energy use wherever they are deployed.

5. Why Geared Motors Are More Sustainable 🌱

Protecting the environment is just as important as lowering costs when it comes to energy efficiency. By using less electricity, geared motors assist businesses in lowering their carbon footprint.

Our geared motors at EMP Drive, Coimbatore, are made with precision engineering, copper windings, and premium laminations to ensure their longevity and environmental friendliness.

6. Cost vs Savings – The Real Benefit

Due to the somewhat greater initial cost, some plant owners are hesitant to make the investment in geared motors. However, the truth is as follows:

In one to two years, energy savings alone will pay for the additional expense.

Lower maintenance results in lower repair costs.

Less frequent replacements are associated with longer motor life.

For the same amount of labor, a geared motor may use 20% less power than a normal motor operating 12 hours a day. That’s tens of thousands of rupees in savings over a year.

7. Features of EMP Drive Geared Motors

Why is EMP Drive trusted by Tamil Nadu’s industries? because we manufacture long-lasting motors.

✔️ Precision-balanced for smooth operation

✔️ Available in multiple HP ratings

✔️ Custom gear ratios for different applications

✔️ Low vibration, low noise design

✔️ Heavy-duty cast iron body

✔️ ISO-certified and tested for durability

Fast delivery, local assistance, and motors customized to your factory’s requirements are guaranteed by our Coimbatore facility.

8. Tips for Choosing the Right Geared Motor

Consider the following when choosing a geared motor:

Load Requirements– How much torque is needed

Speed – Choose the correct gear ratio for your machine

Duty Cycle – Continuous or intermittent operation

Environment– Dusty, humid, or high-temperature areas require special designs

Mounting Style – Foot or flange mounting as per your setup

To guarantee optimal efficiency, our engineers at EMP Drive, Coimbatore, walk clients through these options.

9. Maintenance Tips for Long Life

Despite being low-maintenance, geared motors last longer with routine care:

Clean dust and dirt from vents regularly

Check lubrication in the gearbox

Tighten loose connections and bolts

Inspect bearings for wear

Avoid overloading the motor

We also provide AMC (Annual Maintenance Contracts) for clients across Coimbatore and nearby regions.

10. Why Choose EMP Drive in Coimbatore?

EMP Drive has been one of Coimbatore’s most reputable motor manufacturers for more than thirty years.

✅ 35+ years of manufacturing expertise

✅ Custom-built geared motors for all industries

✅ ISO-certified quality and safety standards

✅ Affordable pricing with long-term reliability

✅ Local support and service for Tamil Nadu industries

Conclusion

Energy waste is no longer an option for factories. Switching to geared motors will increase machine performance, decrease downtime, and prolong equipment life in addition to lowering electricity expenses.

We at EMP Drive, Coimbatore, produce strong, effective, and long-lasting geared motors to assist industry in achieving these objectives.