The cost of energy is going up faster than ever in the modern world we live in now. Electricity is one of the most expensive things to buy every month, whether you run a textile mill, a packaging unit, a pump house, or an engineering plant. This is exactly why more businesses in India are moving to High-Efficiency Motors, especially in places like Coimbatore that are known for making things.

We at EMP Drive, Coimbatore, have seen this change happen for more than 35 years. Companies need motors that are strong, last a long time, and most importantly, use little energy. Depending on the purpose and load, high-efficiency motors can cut electricity use by anywhere from 10% to 25%.

Let’s talk about how high-efficiency motors lower energy bills, why businesses like them, and how they can help you make money in the short and long run.

1. What Are High-Efficiency Motors?

To cut down on electricity losses, high-efficiency motors (rated IE2, IE3, and IE4) are made with new materials, better winding methods, and better engineering.

Compared to regular motors, they lose less in the following ways:

Heat losses

Magnetic losses

Copper losses

Mechanical friction

Our high-efficiency motors at EMP Drive are designed to give maximum power with minimal electricity use. This makes them perfect for businesses in and around Coimbatore.

2. Why Do Motors Consume So Much Electricity?

In most companies, motors use the most electricity. Motors can use up to 70% of the power bill in textile and manufacturing plants.

Reasons include:

Continuous running for long hours

Heavy loads

Poor maintenance

Low-efficiency designs

Voltage fluctuations

A normal motor loses a lot of power as heat. But a motor with high efficiency cuts down on this waste by turning more power into useful mechanical energy. This saves electricity directly.

3. How High-Efficiency Motors Reduce Energy Bills

⚡ Improved Copper Winding Efficiency

Motors that work well use copper that is of a higher quality and has less resistance.

This means:

Less heat generation

Higher performance at lower energy input

Reduced losses during power transmission

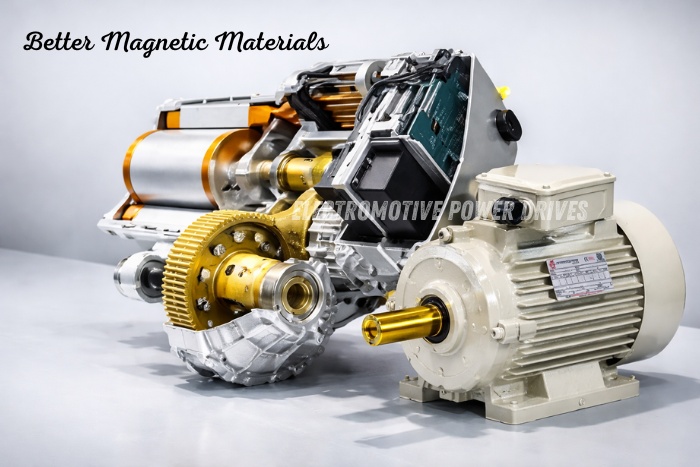

⚡ Better Magnetic Materials

EMP Drive motors use high-tech laminated steel to cut down on hysteresis and eddy current losses. This makes the rotation smoother and uses less power.

⚡ Precision Engineering

Motors that are more efficient are made with tighter tolerances:

Better alignment

Less vibration

Lower friction

All of these things help the motor run easily while using less electricity.

⚡ Lower Operating Temperature

When motors run cooler, they:

Consume less energy

Last longer

Require fewer repairs

A cooler motor is an efficient motor, which means that your monthly power bills will go down.

⚡ Optimized Airflow and Cooling

EMP Drive motors are made with improved cooling fins that get rid of heat more quickly. This means that the motor doesn’t have to work hard or draw more power to keep running at the same speed.

⚡ Higher Power Factor

A higher power factor makes the plant more energy efficient by cutting down on wasted electricity.

4. Long-Term Financial Benefits of High-Efficiency Motors

💸 Lower Monthly Electricity Bills

When motors run for 12 to 24 hours a day, even a 10% savings makes a big difference.

💸 Reduced Maintenance Costs

Fewer problems mean better materials and less heat production.

💸 Extended Motor Life

Motors that are 30–40% more efficient last 30–40% longer than regular motors.

💸 Lower Replacement Cost Over Time

High-efficiency motors don’t break down as often because they run cooler and better.

💸 Reduced Carbon Penalty (Environment-Friendly)

There are many government programs that urge people to use machines that use less energy. Firms might be able to get rebates or rewards for following the rules.

5. Industries That Benefit the Most

EMP Drive’s high-efficiency motors are used a lot in:

🧵 Textile mills

🛠 Engineering factories

🍲 Food processing plants

🏭 Manufacturing units

💧 Pumps and water treatment

🚚 Material handling

🏯 Chemical industries

In all of these fields, the motor runs all the time, so performance that saves energy is very important.

6. Features of EMP Drive High-Efficiency Motors

Our motors include:

✔️ IE2 / IE3 / IE4 Efficiency Options

✔️ High-grade copper windings

✔️ Low-noise, vibration-free design

✔️ Heavy-duty cast iron body

✔️ F-Class insulation for temperature resistance

✔️ IP55 / IP56 protection for harsh environments

✔️ Precision-balanced rotors

✔️ Custom speed & torque configurations

Every motor made by EMP Drive in Coimbatore goes through strict quality checks to make sure it meets the highest standards of performance.

7. Choosing the Right High-Efficiency Motor

When selecting your motor, consider:

Power Rating (HP/kW)

Type of Application

Duty Cycle (Hours per day)

Voltage Consistency

Ambient Temperature

Desired Speed (RPM)

Mounting Type

At EMP Drive Coimbatore, our team helps businesses choose the best motor for their needs by giving them personalized advice.

8. Maintenance Tips to Maximize Energy Savings

Even a high-efficiency motor needs basic care:

✔️ Keep the motor clean

Dust and fluff can block airflow.

✔️ Ensure proper lubrication

Poor lubrication increases friction and reduces efficiency.

✔️ Check load conditions

Avoid overloading or underloading the motor.

✔️ Monitor voltage regularity

Voltage fluctuations affect performance.

✔️ Tighten fittings periodically

Vibrations can loosen mountings over time.

✔️ Inspect bearings and insulation

These are critical for smooth operation.

For companies that want easy motor maintenance, EMP Drive also has AMCs (Annual Maintenance Contracts) available.

9.Why Coimbatore Is the Hub for High-Efficiency Motors

Coimbatore has become one of India’s strongest industrial hubs due to:

Skilled engineering workforce

Strong manufacturing culture

Reliable supply chain

Focus on innovation and quality

This makes Coimbatore the right place for EMP Drive to be based so that we can offer world-class motors along with quick customer service and local knowledge.

10. The Future of High-Efficiency Motors

The next generation of motors will focus on:

IE4 & IE5 ultra-high efficiency levels

IoT-enabled monitoring

Predictive maintenance using AI

Lighter materials with better thermal performance

Smart speed control for dynamic loads

We are already working at EMP Drive in Coimbatore to add these technologies that are ready for the future.

Conclusion

The use of high-efficiency motors is not just a trend; they are also a good investment that quickly pays for itself through lower power costs, less downtime, and higher output.

Our goal at EMP Drive, Coimbatore is to make motors that help businesses save power and run smoothly and efficiently. We know exactly what businesses need to lower costs and improve performance because we’ve been in the game for over 35 years.

Getting high-efficiency motors is one of the best things you can do for your business if you want to save energy, cut down on waste, and boost output.

📞 Reach out to EMP Drive, Coimbatore today to upgrade to High-Efficiency Motors and start saving on your energy bills.